Our Company

Partnering & Collaboration

The importance of collaboration

As the market demand for offsite manufacturing grows, so does the need

for sharing information across all phases of construction. After all, offsite

manufacturing caters to ‘just-in-time’ production – this relies heavily on all

parties sticking to tight timeframes to avoid slippage.

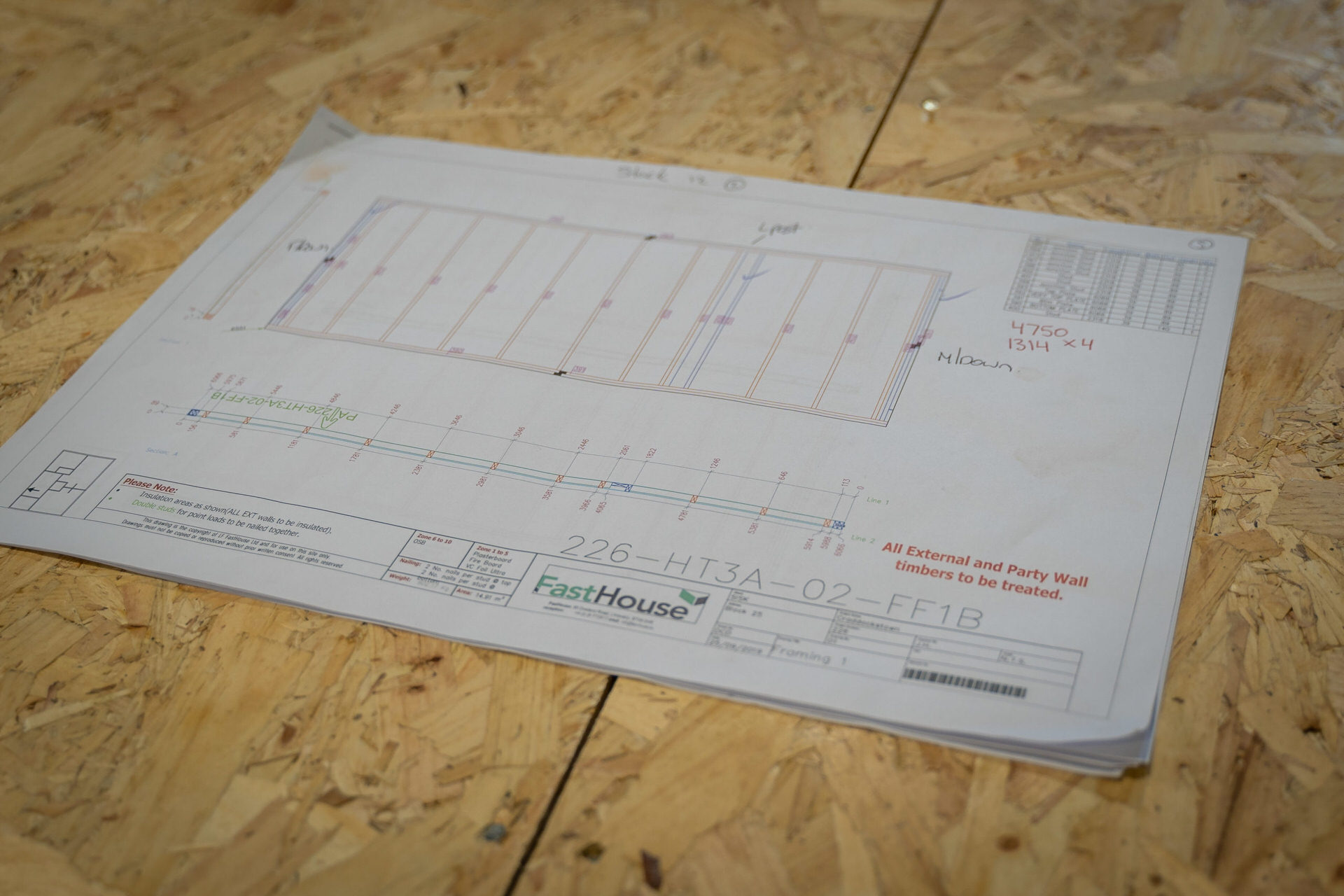

FastHouse is dedicated to promoting collaboration with all project

stakeholders, from clients and advisors to design consultants, on-site

construction crew and end users. We understand that early engagement, a

strong partnership and effective communication are all key to making sure

the project is delivered as efficiently and successfully as possible.

Getting these elements right will not only improve control over a project

but will also ensure it is delivered on time, with reduced costs and high

levels of accuracy.

Key Benefits

- Accurate planning, coordination and design processes

- Accountability for potential slippage

- Optimised and efficient manufacturing

- Improved product value

- Shared benefits for all stakeholders

Why Choose FastHouse

Early engagement and collaboration ensures that Design for Manufacture principles are optimised.

Systems