The planet has more trees now than it did 35 years ago.

Our Company

Corporate Social Responsibility

At FastHouse, we make sure to act on sustainability, not just with the products we supply, but through our manufacturing processes too. Below we have broken down the actions we take to be more sustainable, so you can learn about the benefits.

Greener Product

Timber is the perfect building material as it is natural and renewable. Coming from carbon neutral trees, every cubic metre saves 0.8 tonnes of CO2 compared to concrete or steel. This means a typical two storey building of 100m2 saves 4 tonnes in CO2 emissions.

Because of their low thermal mass, timber frame structures are also energy efficient as they are quicker to heat than masonry constructions. The energy you save will also save you money.

Greener Construction

By practically eliminating waste during manufacturing, less waste ends up on-site. This helps to reduce the millions of tonnes of construction waste that goes to landfill each year – not forgetting to mention the added benefit of not having to pay for expensive removal costs either.

Greener Manufacturing

We take the safety of our employees and contractors very seriously. Constructing timber frames with an offsite manufacturer (OSM) provides a safer, more predictable environment than a conventional construction site. Basing the bulk of the construction work offsite means there are fewer on-site hazards – such falls caused by wastage and materials causing trip hazards. There is also less risk of falling from a height, and less risk of vehicle accidents as there will be fewer vehicles on site as most of the work will be done offsite.

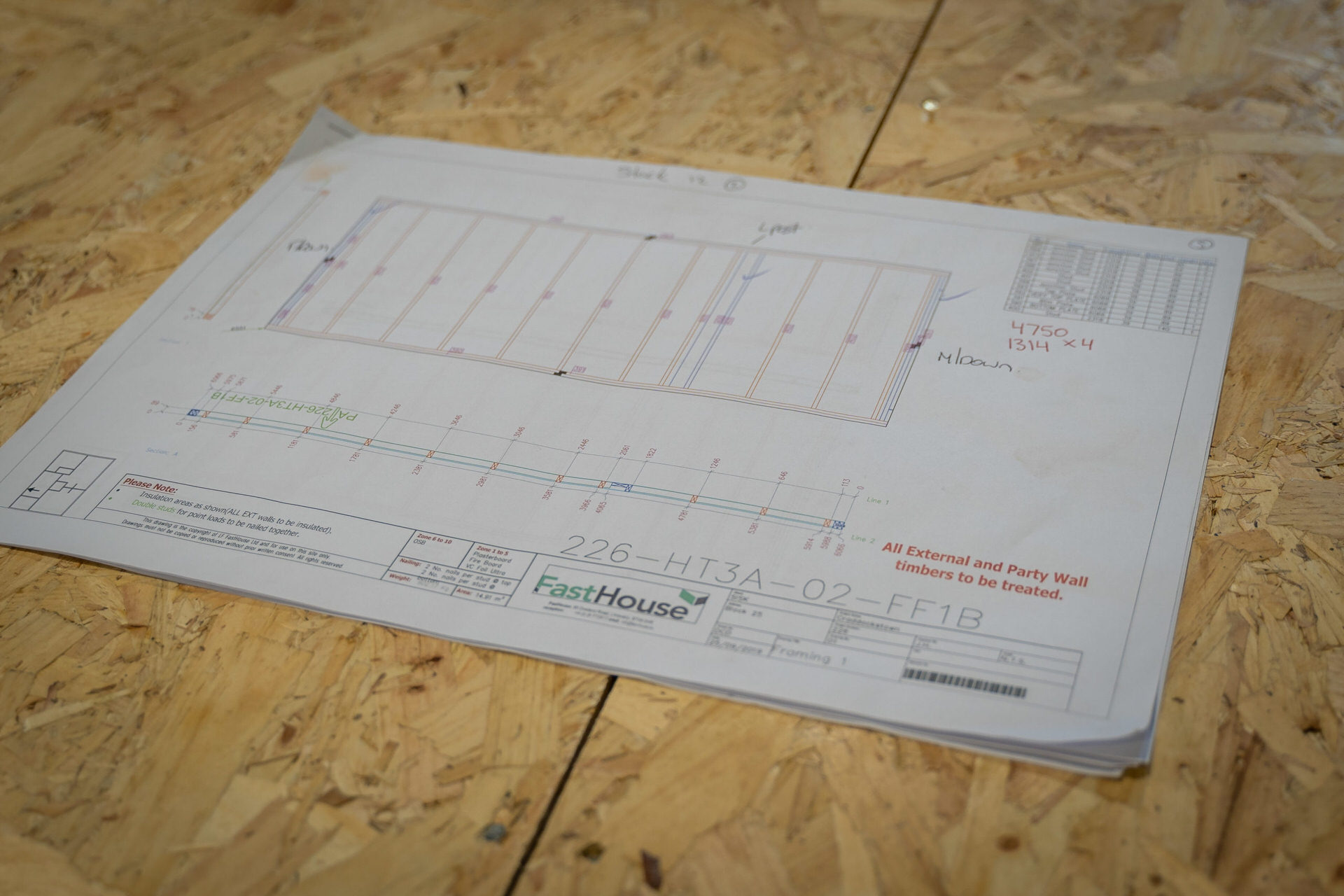

The FastHouse factory uses 4 manufacturing lines which further reduces the risks to our manufacturing personnel. Our precise factory engineering maximises material efficiency too. Quantities can be calculated with accuracy and precision which reduces waste throughout the entire construction project.

Greener Community

The FastHouse timber frame system also boasts advantages for the community. The main culprit in carbon emissions, as well as noise pollution, is transport. Using an OSM greatly reduces the need for vehicles travelling to and from the construction site with materials. A study by WRAP concluded that site traffic is reduced by 83% compared to on-site construction which reduces local traffic, and blocked parking spaces and access routes.

Better still, using a timber frame system gives an accelerated build programme which minimises disruption to the local community, including the length of time unsightly construction sites are around, making sure FastHouse remains considerate of people who reside nearby the construction site. We want to ensure people have a fond perception of FastHouse, therefore we make sure we cause as little disruption possible during our projects.

Timber is renewable

Here are some key statistics:

European forests have been growing by over 1,500 football pitches every day.

European softwood plantations are currently in surplus supply. Standing stock has increased by 252 million hectares.

28% of the world’s wood harvest is used for construction.

Timber uses 5 times less energy to produce than concrete.

Timber uses 6 times less energy to produce than steel.

Why Choose FastHouse?

The construction sector is one of the largest contributors of greenhouse gas emissions. Here at FastHouse we provide more sustainable alternatives to traditional building methods throughout the entire process, from sourcing materials to the manufacturing and construction of the final build.

Systems