Process

Installation

Erection Sequence

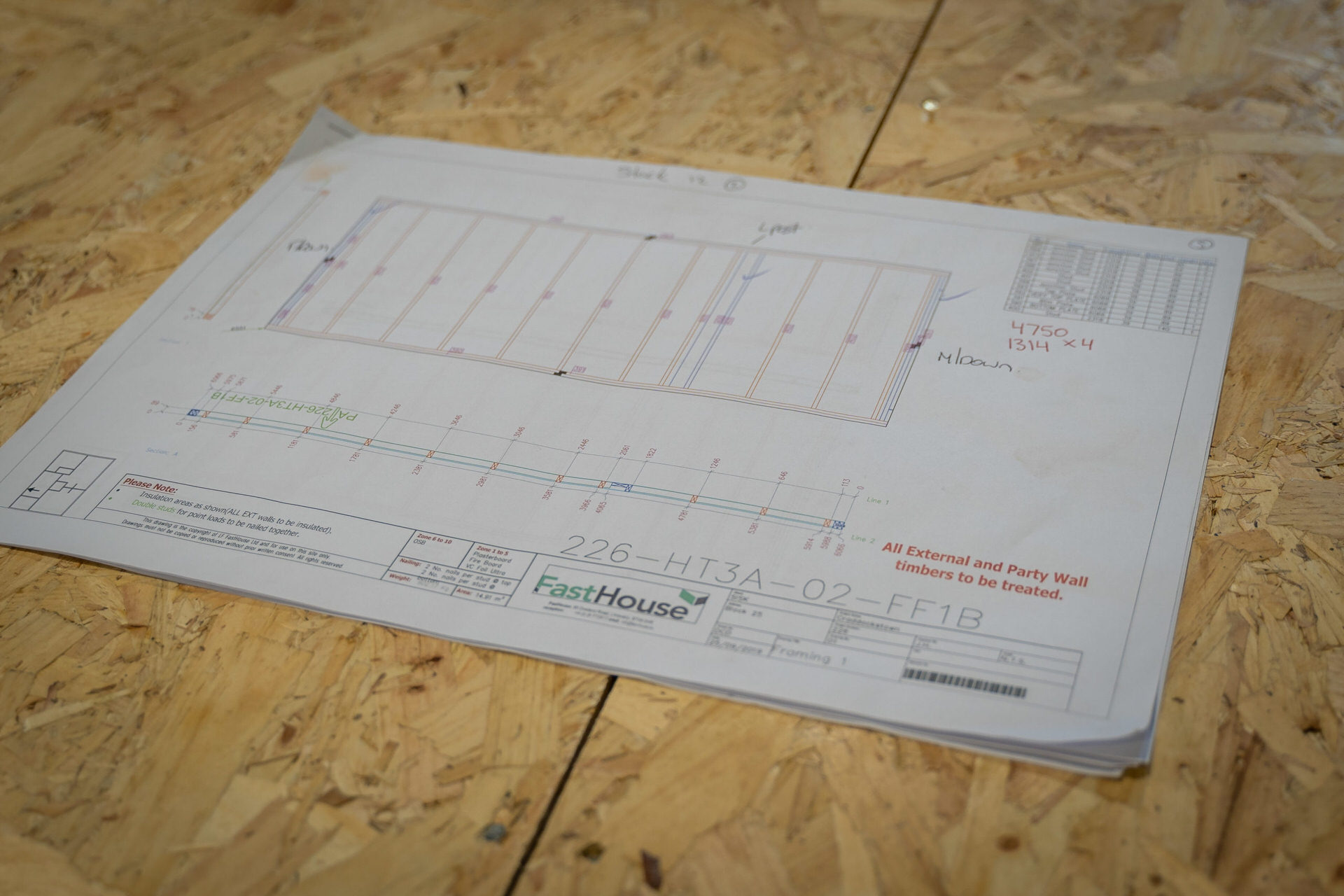

- FastHouse erection is in accordance with all of the relevant standards.

- Base brackets are fitted to the substructure and horizontal levelling system and aligning is carried out prior to the timber frame kit arriving on-site.

- Panels are lifted and locked into place with mechanical jointing brackets

- Panels are fixed to a concrete base with pre-galvanised mild steel

- The location of mechanical connecting brackets for all walls has been predetermined, eliminating the need for the crew to plumb and align walls. This process ensures quality and speed on-site

- Exterior walls are sealed with mastic/air-seal at the erection stage. This process gives additional vapour control measures at corners and junctions, using the fixing brackets, which achieves more efficiency in air tightness

- Site checklist and sign off.

Required checks during the construction phase are followed up with completed check lists and relevant sign off certifications stating that the timber frame structure has been erected in accordance with the relevant standards.

Advanced components added to FastHouse timber frame systems:

The secret to a fast and accurate assembly is through the use of innovative installation techniques. The below elements eliminate snagging on-site and ensure there is no need to check timber frame components are accurate, square, plumb, and with correct connection details.

The FastHouse timber frame levelling system provides:

- The combined function of levelling and fixing the sole plate to the foundation

- The system transfers vertical and lateral loads from the wall to the foundation

- It has the flexibility and adaptability to accommodate up to 30mm deep out of tolerance

- The system ensures we work off a square level platform every time

- If required, a non-shrinkage bed of levelling compound can be applied to the base of all walls to minimise movement, tolerance issues and gaps beneath the sole plate.

FastHouse Mechanical fixing bracket:

- Stainless steel Connector brackets connect one wall to another

- Locks the connection with a slide-in fixing

- Catches the holding screw and lines the connection into position

- Helps create an air tight seal

- Ensures the structure is stabilised from the first corner

All of the above points equate to fast and accurate wall connection details meaning simple and speedy erection for the assembly crew.

Furthermore, the main contractor will have less snagging to carry out on the timber frame kit.

Why Choose FastHouse

A set of semi-detached houses are typically weather-tight within 2 days of delivery.

Recent Projects