Hybrid System

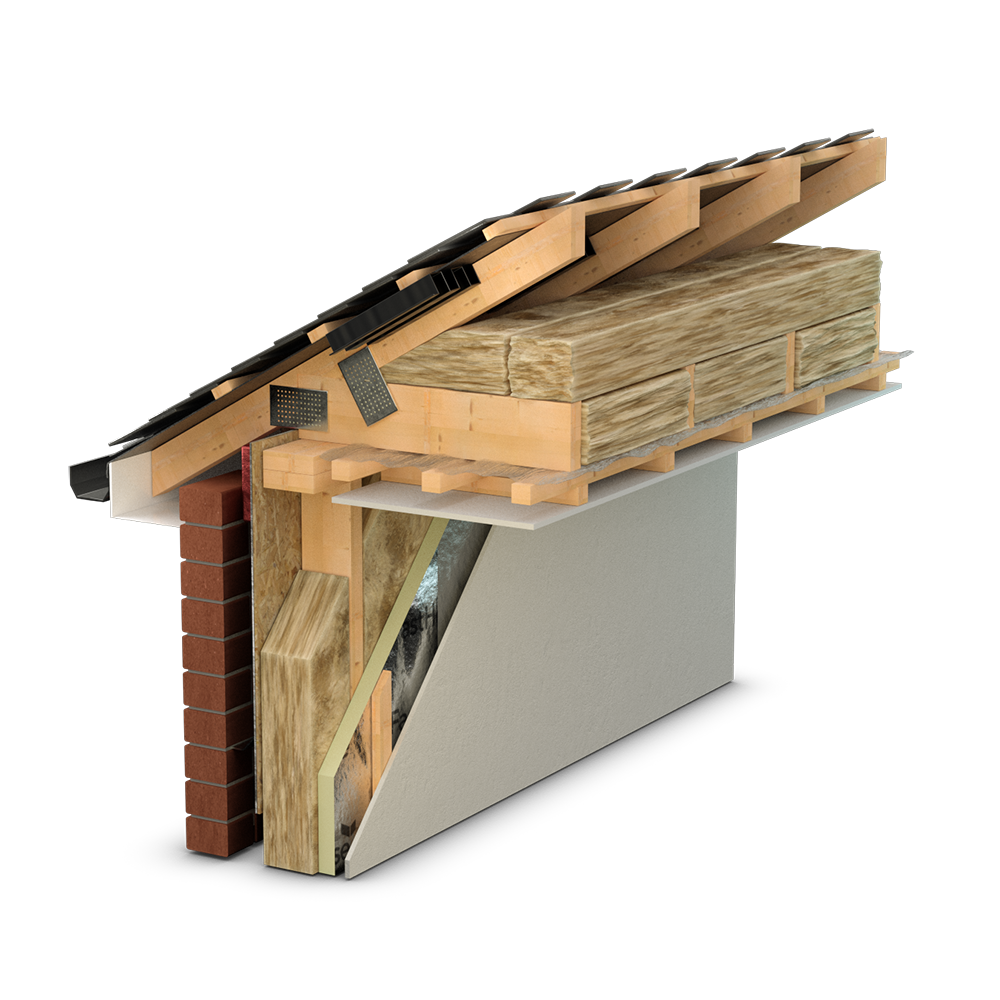

Roof Structure

Bespoke to your project, choose from a variety of styles, weights and widths, with Fink and W/W trusses best used on larger spans, whilst raised tie and scissor trusses lending themselves to better vaulted ceilings.

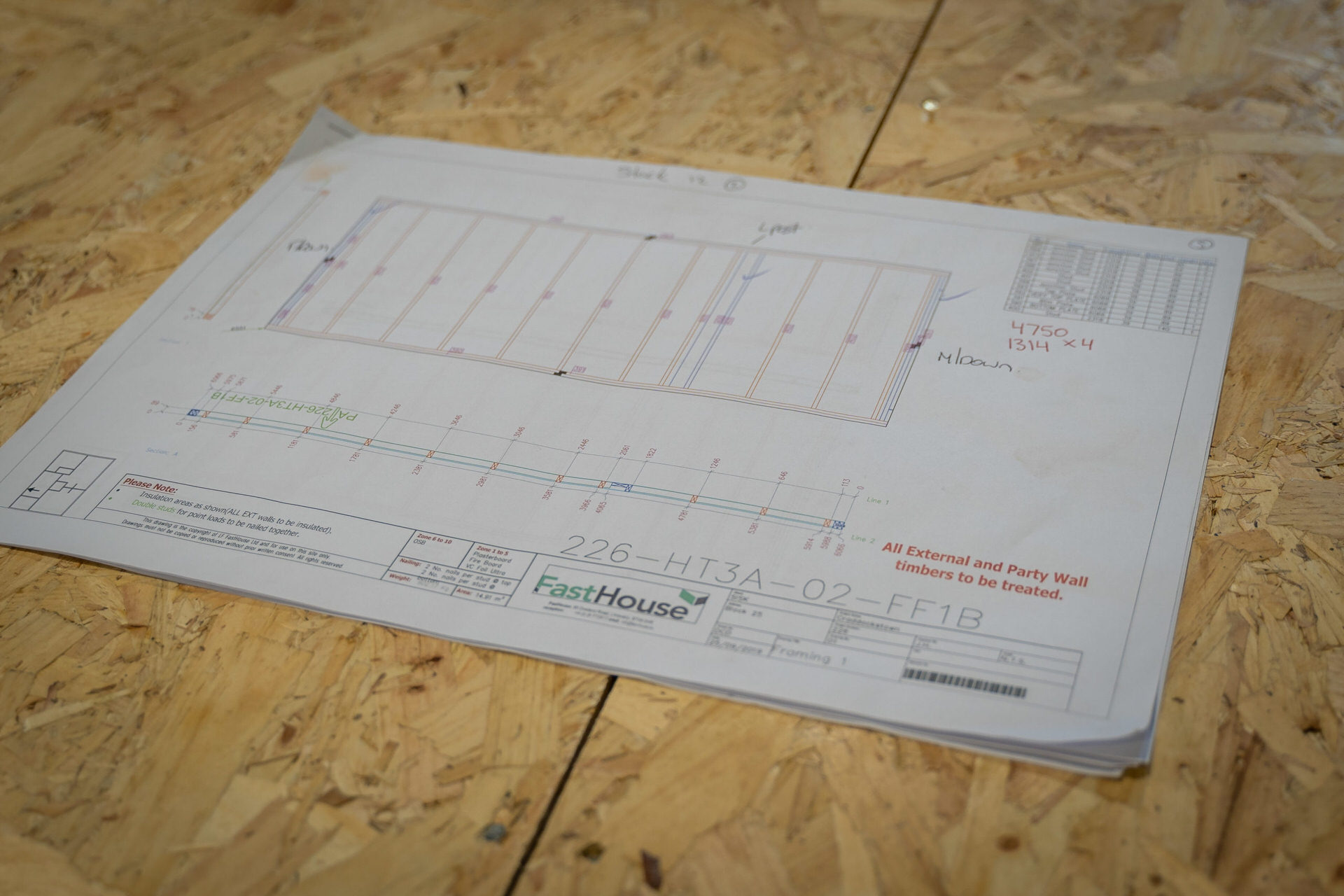

FastHouse designs and details the roof structure not only to provide a weather-tight envelope to the building within 24 hours, but to also provide stability.

These affordable, simple-to-erect engineered roofing structures use 40% less timber than traditionally formed roofs. Plus, ours are engineered using computer designed and factory assembled units, resulting in increased quality assurance.

If required, FastHouse can also supply the relevant insulations and lining to satisfy specified thermal, acoustic, and fire performance criteria.

- Roof Finishes: Install slating or tiling roof cladding

- Roll out Eaves ventilation system

- Tiling battens

- Breather Membrane

- Backing board for fixing facia, supplied & fitted

- Horizontal cavity barrier and pvc DPC

- Prefabricated Roof Trusses, supplied & fitted

- 35mm x 60mm service cavity Battens to support all board edges

- Airtight membrane

FastHouse Roof Panel System

As we have an increased demand for loft living solutions, FastHouse will soon be able to offer a ‘room-in-roof’ Closed Panel System. These systems will provide a host of benefits including:

- U-values as low as 0.11 W/m2K

- Pitches up to 60 degrees

- A range of fascia and soffits

- GRP or Traditional Timber Dormers

- Velux Roof Window

Our company

Why Choose FastHouse?

FastHouse has been developed in response to a market need for high performance, energy efficient and cost effective construction systems which bring the benefits of being produced in factory controlled environment.

FastHouse offer innovative offsite manufacturing solutions to:

- Address the shortage of skilled construction labour

- Reduce construction time frame and providing certainty to program

- Remove the risk of design, materials and workmanship failures

FastHouse products are manufactured in a 200,000 ft2 state of the art, multi-million pound production facility in Limavady, Northern Ireland.

Our Company