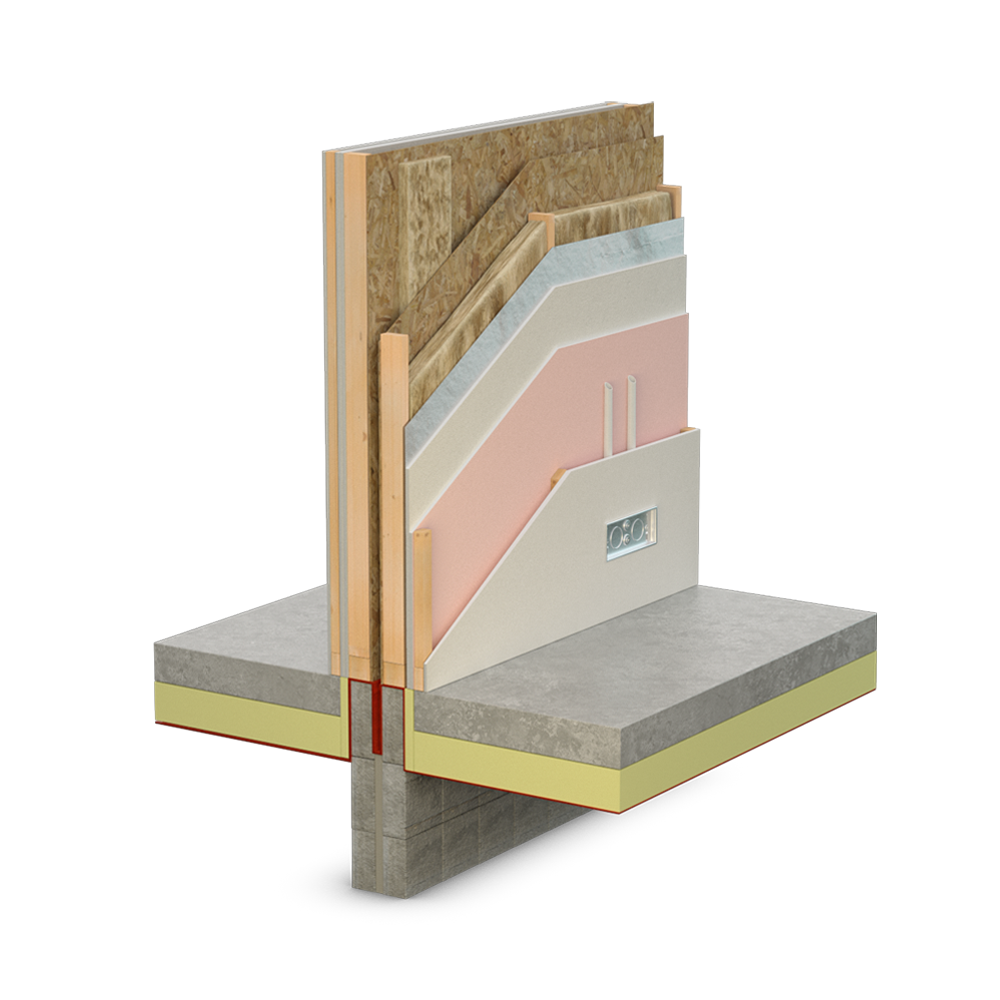

Closed System

Party Wall

The isolation of the leaves, the mass and thickness of the boarding, and the insulation all provide the wall with an acoustic performance exceeding a sound reduction of 70dB. The system is also fire-tested to provide a fire resistance of REI60. As part of our party wall system, FastHouse site-installs a wire reinforced rock fibre vertical fire stop sealing the cavity at the wall ends, running from DPC level to this underside of the non-combustible board at the top of the party wall. At the junction between the party wall and external wall, we place a vertical firestop that is the full width of the party wall into the external wall as well.

At the junction where the floor cassettes meet the party wall, horizontal fire stops are site-installed along the full length of the party wall within the cavity between both leaves.

- 9mm OSB Sheating Board to cavity side of both leaves

- Cavity adequately sealed against fire with Rockwool wired matt used as vertical & horizontal barriers and fire stops. Cavity can be fully insulated if required to achieve zero U Value

- Air tight membrane factory fitted

- Min 40mm cavity between the 2 leaves of the separating wall

- Timber 89mm studs untreated C16, All cut ends Treated

- Sole Plates Treated Timber C16 with DPC fitted

- Insulation – Party walls fully insulated with mineral wool to meet fire & acoustic regulations

- Factory fitted 15mm Type A plaster board to meet fire & acoustic regulation

- Factory fitted 15mm Type F plaster board to meet fire & acoustic regulations. Type F overlaps joints of type A

- Party Wall service void 38mm x 46mm Battens

- Electrical conduits / boxes, and additional layer fo plasterboard to internal side of service void only offered in fully closed system

Our company

Why Choose FastHouse?

FastHouse has been developed in response to a market need for high performance, energy efficient and cost effective construction systems which bring the benefits of being produced in factory controlled environment.

FastHouse offer innovative offsite manufacturing solutions to:

- Address the shortage of skilled construction labour

- Reduce construction time frame and providing certainty to program

- Remove the risk of design, materials and workmanship failures

FastHouse products are manufactured in a 200,000 ft2 state of the art, multi-million pound production facility in Limavady, Northern Ireland.

Our Company